The Process of Our Composite Fences

Our composite fences—ranging from privacy fences to ornamental pickets and rails—set the industry standard for strength and durability. But what’s behind this exceptional quality? The secret lies in our fences’ high glass content and our specialized pultrusion manufacturing process.

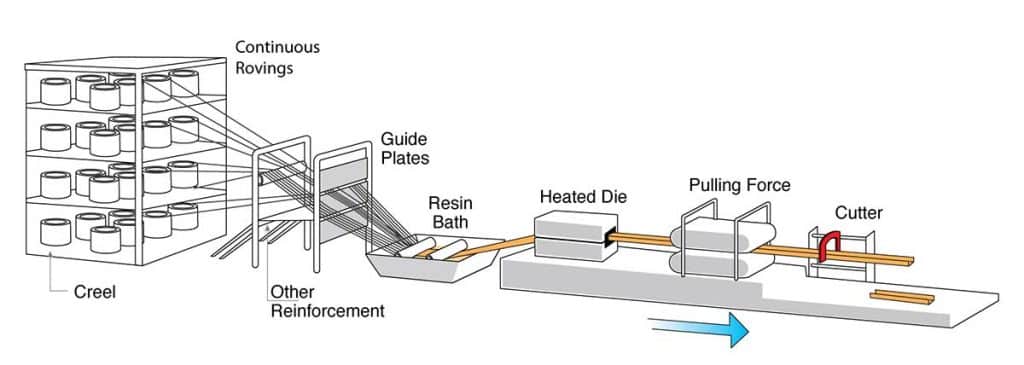

Pultrusion is a composite manufacturing method in which materials are drawn through a continuous, 100-foot-long machine. Glass fibers, such as roving, are pulled through a resin bath infused with a proprietary chemical formula that forms our patented composite products.

Next, this blend of glass, resin, and other components is pulled through steel dies heated to over 400°F. As it moves slowly through these heated dies, the material cools upon exit, forming a perfectly shaped, high-strength product. The continuous process allows for precision cutting and assembly to meet your specifications, ensuring a fence that performs for years to come.